Activated Carbon SIPHON Tank

|

Activated carbon treatment has been widely adopted due to the strengthening of the effluent standard and legal revision, as well as instruction to switch from discharge into rivers to discharge into sewerage areas and necessity for compliance with environmental programs under ISO 14000. In conventional activated carbon treatment systems, activated carbon is firmly fixed in the upper layer, and it is replaced with new activated carbon although activated carbon in the lower layer is still usable. In addition, since the surface of activated carbon is coated with suspended substances, internal absorption performance cannot be fully utilized, and thus early replacement is necessary. Therefore, it has been very difficult to make best use of the capacity of activated carbon. We solved these problems and developed the “ACTIVATED CARBON SIPHON TANK,” which is an innovative activated carbon absorption facility that largely extends the life of activated carbon. ACTIVATED CARBON SIPHON TANKs can significantly reduce the cost for replacing activated carbon and maintenance costs. It also reduces the amount of energy consumed in reactivating carbon or producing new carbon, thereby largely contributing to the conservation of the global environment. |

Characteristics

| 1) | Significant extension to the life of activated carbon |

| The life of activated carbon can be significantly extended due to prevention of fixation of activated carbon and exfoliation of suspended substances that clog up the absorption pores. | |

| 2) | Significant reduction of maintenance costs |

| Since the life of activated carbon can be significantly extended, maintenance costs, including the cost for replacing activated carbon, can be significantly reduced. In addition, since suspended substances attached to the surface of activated carbon are exfoliated through siphon cleaning and the purpose of backwashing is to discharge the exfoliated sludge, the amount of backwash water can be significantly reduced. | |

| 3) | Since suspended substances are exfoliated, a sand filtration system in the previous step is not necessary any more. |

| Since suspended substances attached to the surface can be exfoliated, it may not be necessary to attach a sand filtration system in the previous step if the SS concentration in the raw water is 10-15mg/L. Note that the SS concentration to which suspended substances can be removed changes according to the property of raw water. | |

| 4) | Considerations are given to environment problems, including compliance with ISO14000. |

| Since the life of activated carbon can be extended, ACTIVATED CARBON SIPHON TANKs can contribute to complying with ISO14000. It also contributes to reducing energy consumption and dust generation when reactivating carbon or producing new carbon. In addition, the amount of backwater can be reduced.

*Activated carbon to be packed is designated by us. We propose activated carbon of the optimum grade according to specific purposes (such as subject to removal). |

Why the life of activated carbon can be extended?

Reason1)

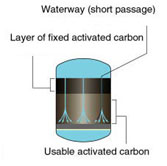

Fixation in the upper layer can be prevented, and all activated carbon including that in the middle and lower layers is able to absorb.

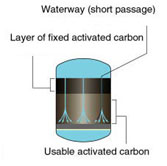

■In a conventional activated carbon facility, fixation of activated carbon occurs in the upper layer and a waterway is formed, and absorbed substances sometimes go through a short passage. As a result, it is necessary to replace activated carbon although activated carbon in the middle and lower layers are still usable.■ACTIVATED CARBON SIPHON TANK prevents fixation by mixing all of the activated carbon and shuffles activated carbon in the upper layer and that in the middle and lower layers, which is still usable. Thus, activated carbon in all layers absorbs so that the life thereof can be extended. Incidentally, activated carbon is stratified through backwashing, so there will be no turbulence in the mass transfer zone.

Reason2)

Suspended substances are exfoliated and sufficient absorption inside the activated carbon is thus possible.

■If suspended substances are attached to the surface of activated carbon, macropores become clogged. If macropores become clogged, absorbed substances are prevented from going into internal pores, so the rate of effective utilization of activated carbon becomes lower. (Figure A)■Since backwashing by a conventional activated carbon facility has only a small effect of exfoliating substances attached to the surface of particles, activated carbon is replaced without sufficiently utilizing the absorption capacity of its internal pores. (Figure B)

■ACTIVATED CARBON SIPHON TANK secures an entrance where substances attached to the surface of particles are completely exfoliated and absorbed, so the life of activated carbon can be extended. (Figure C)

| Conventional activated carbon facility | |

|

|

|

|

Activated carbon in the upper layer fixes and only part of the entire

activated carbon can be used. |

| Activated-Carbon Siphon Tank | |

|

|

|

|

The entire amount of activated carbon can be used, so the life thereof is extended. Fixation is prevented, and activated carbon is shuffled. |

Experiment

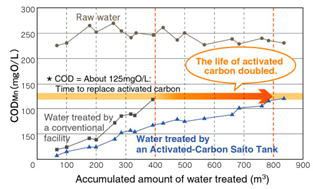

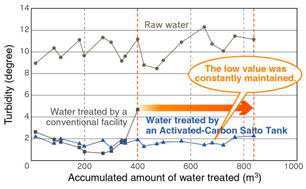

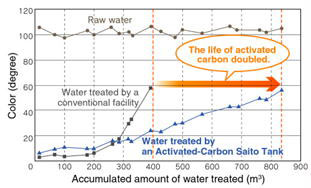

Comparative experiments between the absorption capacity of a conventional activated carbon absorption facility and that of an ACTIVATED CARBON SIPHON TANK.

The life of activated carbon was extended in terms of COD and color!

The graph below shows the result of comparative experiments between a conventional upward-flow activated carbon absorption facility and an ACTIVATED CARBON SIPHON TANK under the same conditions in an actual industrial waste disposal facility.

|

||||

|

||||

|

||||

| *The life of activated carbon differs according to the property of raw water, so it is not the same in all cases. | ||||

Line up

Standard Specifications

| Material | Body : SUS304L/ Motor bearer・legs : SS400 | |||

|---|---|---|---|---|

| Types | Body diameter (mm) |

Cartridge diameter (mm) |

Motor (kW) |

Amount of treated water (m3/H) *LV=10 |

| ACST-1200 | Φ 1200 | Φ250 | 5.5 | 8.5 |

| ACST-1500 | Φ1500 | Φ400 | 7.5 | 13.3 |

| ACST-1600 | Φ1600 | 15.1 | ||

| ACST-1800 | Φ1800 | 19.1 | ||

■We propose the specifications of activated carbon and the size of tank to meet your needs after analyzing the raw water.

| ■ Reference | |

| ◆Private sector

|

|

| Research & Develop Laboratory ST-1500 + ACST-1700 Industrial waste and sewage treatment 25CBM/hr |

|

|

|

|

| Plating Company ACST-1500 Plating waste water treatment 10CBM/hr |

|

|

|

|

| Car Parts Company ST-1600 + ACST-1800 X 2units 20CBM/hr Dissolved-air flotation treated wastewater |

|