New Color Cutter Light

Arsenic (As)

De-Color

Humic Acid contains Iron and Manganese in groundwater. It is a constituent of humus, the organic component of soil, and dissolved as macromolecule Colloid into groundwater. Normally Humic Acid is removed by Activated Carbon but Macro pores cannot absorb Colloid enough and effective utility is low. As a result, that shortens the media life. On the other hand, our product “New Color Cutter Light (NCCL)” is a high Manganese dioxide media with improved color removal capacity than the former “Color Cutter L”. The removal method is different from Activated Carbon; NCCL acts as an oxidation catalysis on Humic Acid under Chlorine-existing conditions so that it can expand its removal life. Since removal of Humic Acid by “NCCL” is only for dissolving Humic color, it will avoid occurrence of SS and clogging. Therefore, it can reduce backwashing operation to once or twice a week.

FEATURES

- Stable treatment

NCCL has similar removal capacity as the other special media. Only to combine Hypochlorous acid, Humic color can be removed and stabilize water quality. - Small space and cost

It can be expected to be highly effective to utilize PAC but an aeration tank is unnecessary except for special treatment. It provides quality water by contacting raw water directly. So that you only to need a small extra space and can reduce maintenance cost because of not using PAC or other chemical agents.

PROPERTIES

| Appearance | Effective Size (mm) | Uniformity Coefficient | Specific Gravity (g/cm³) | Bulk Density (g/cm³) | Porosity (%) |

|---|---|---|---|---|---|

| BLACK | 0.35 | Under 1.4 | 2.77 | 1.0~1.1 | 62.0 |

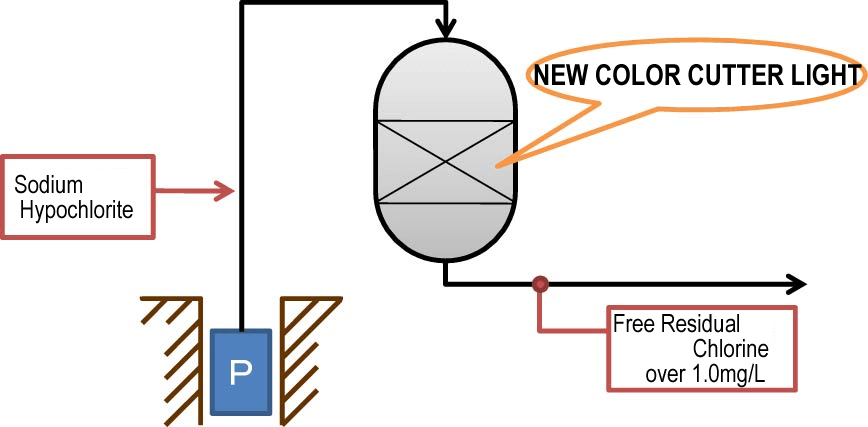

MECHANISM of COLOR REMOVAL

When Humic Acid comes into contact with NCCL, Humic color is removed. Even if the NCCL removal capacity goes down in the short term., if over 1.0mg/L of Free Residual Chlorine exists in treated water, NCCL acts as oxidation catalyst and sustains its removal capacity. This mechanism is similar to contact oxidation process for Manganese removal treatment.

USAGE

- Oxidizing agent injection

When reducing substances contact NCCL, NCCL loses its capability of removing colors and manganese.

To avoid this, it should be infused with an Oxidizing agent such as Sodium Hypochlorite, Chlorine, Ozone etc. In case of Chlorine, for example, it should be a controlled concentration of Free Residual Chlorine over 1.0mg/L in treated water. - Layer thickness and Flow rate

We recommend to decide the thickness of the layer in accordance with SV=10. Absorption time is completely different depending on the condition of raw water, but if the flow rate needs to be increased, we recommend designing SV to be high. In case of Iron and Manganese dissolving together, Iron is acid removed first, then Manganese, and finally Humic color. If high concentrations of Iron and Manganese are dissolving and moreover, high Humic color is dissolving, it is very effective at removing those matters via two filter vessels on a series ⅽonnection; pre-system is for Iron and subsequent is for Manganese and Humic colors.

NOTICE

* Please wear a dust mask, when you set NCCL into the tank. We conduct Hypochlorous acid treatment to NCCL before it is transported from our plant. Backwashing 2-3 times / 10-20 minutes is needed to remove small particles but it does not need to be soaked in Hypochlorous acid. But if the Hypochlorous acid treatment is needed, soak in it 1000mg/L in over 12 hours. However, after backwashing, some small particles may still remain but it does not affect any filtration effects.