SIPHON WASHING SYSTEM(SWS)

Able to attach on your current system

Do you face issues like unstable treated water quality or tiresome replacement of filter media?

These are all caused by the filter media itself. We came up with an idea through our various knowledge, experiences, and achievements, and finally produced an exterior tank filter device, SIPHON WASHING SYSTEM (SWS) which can advance your existing filter tank by just putting it on the outside.

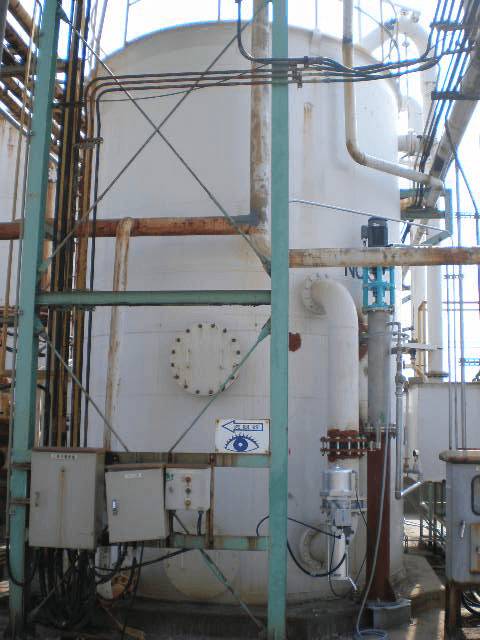

SWS able to attach any Tank.

- Install SWS on any tank

Just set SWS on the existing tanks to add a strong washing function to it. Of course, it applies to any downstream filter tanks. - Compact Design

Considering any situation, we achieved a compact design including control device so that can fit into small spaces. - No need to change tank programs

Since SWS operates during the backwashing process, there is no need to incorporate a special program into the conventional operation process system. - Apply to multi-layer like filter sand and Anthracite

SWS applies to clean up not only the filter sand but also Anthracite and can set both mono-layer and multi-layer tanks.

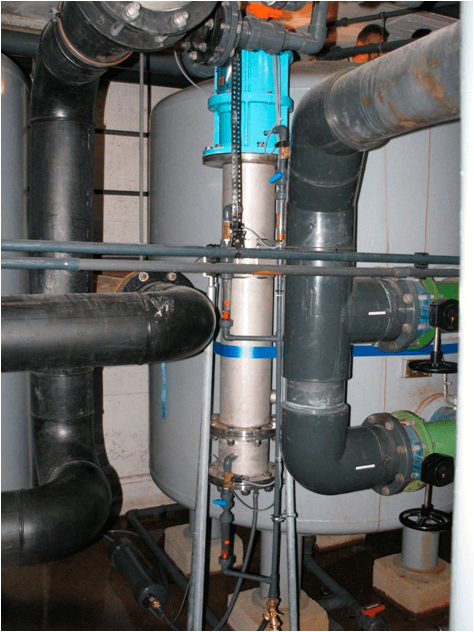

Collaboration with German Company

We produced SWS here in Japan and brought it to Germany first to experiment on its capacity with our exclusive distributor in Germany. They did demonstration tests on actual filter tanks.

Since this test succeeded, we have started promoting and selling it from April 1st, 2009 in Japan and around the world as well.

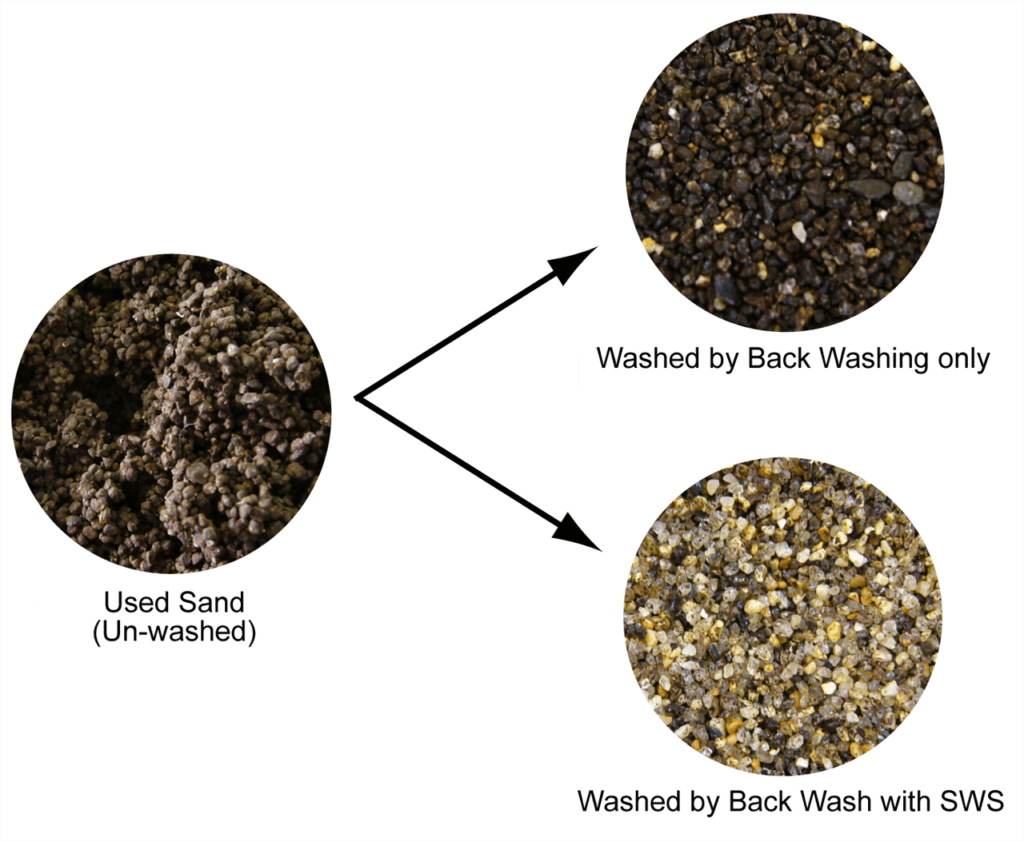

Also, we did the same test at the water purification plant in Japan to reconfirm the SWS washing capacity such as effects of SWS, and fixation sludge covering the media were removed comparable to new sand.

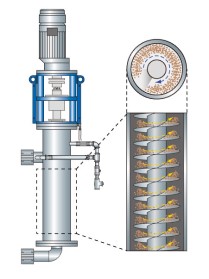

SIPHON Washing System

| Principle of SIPHON WASHING | |

|---|---|

|  |

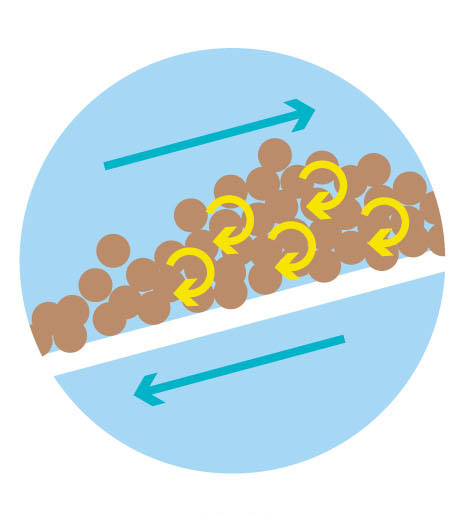

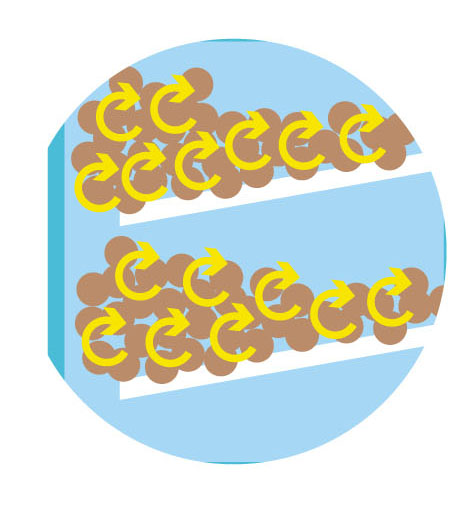

| A vortex flow is generated By the gravity of particles and the lift force created by the screw. | Particles running outward due to the centrifugal force generate a vortex flow. |

UNIQUE PERFORMANCE

- High Cleaning Effect

Backwashing and air-washing can only prevent clogging. However, even stubborn sludge can be removed by kneading action among filter media particles. Therefore, filter media can be cleaned up to under 30 degrees of washing turbidity comparable to the new sand. - Filter media cannot be crushed using by Kneading action method.

Due to filter media washing each other by kneading action, filter media will not be crushed although the sludge attached tightly to the surface of the sand is removed. Therefore, filter media can be always kept clean. - The outflow of exfoliated sludge can be avoided or significantly reduced.

Through the high cleaning effect, the outflow of exfoliated sludge into treated water can be avoided or reduced, and can maintain stable water level continuously. - Significantly reduces the outflow of filter media.

Regardless of the particle sizes, filter media runs off during the backwashing process. SWS can significantly reduce the outflow by keeping filter media in the same condition as new filter media.

SWS Flow Chart

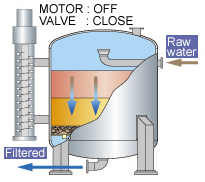

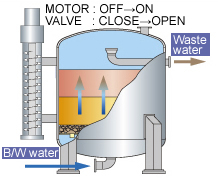

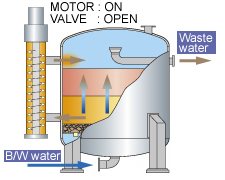

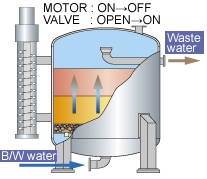

| ①Filtration | ②Backwashing/ SIPHON WASHING SYSTEM | ③SWS washing | ④Backwashing |

|---|---|---|---|

|  |  |  |

| Filtration process proceeds in a conventional way. At that time, Valve is closed in order to avoid flowing untreated water into SWS device. | a) Backwashing process starts as a conventional filter device. b) At the same time, valve connected to SWS opens and slurry comes into SWS. c) Siphon washing starts by siphon motor rotation. | a) SIPHON WASHING SYSTEM finishes first. b) Remaining slurry flows back into the tank. c) Exfoliated sludge flows out the tank by backwashing. | After all the backwashing process is finished, upper valve closes and returns to normal filtration process. Note: Apply to multi-layer, sand media and Anthracite. |

In the filtration process, water filtration is conducted the same as the conventional way.

Adding SIPHON WASHING SYSTEM to conventional backwashing process can provide high quality and effective washing actions and keep media clean.

| Height (mm) | Width (mm) | Weight (kg) | Capacity (L-sand/min) | Motor (kW) |

|---|---|---|---|---|

| 2200 | 400 | 260 | 150 | 2.2 |

Reference

●Public sector

UENO ZOO in TOKYO Metropolitan

SWS X 6 units

Pool water treatment for animals

ASAHIYAMA ZOO in ASAHIKAWA City

SWS X 3 units

Pool water treatment for animals

●Private sector

Brewery Company

SWS X 8 units

Process water treatment for beer

SHOWA DENKO K.K.

SWS X 2 units

Calcium contained water treatment

ASAHI TOSTEM EXTERIOR BUILDING MATERIALS Company

SWS X 4 units

Pretreatment for process water

●Overseas

GERMAN COMPANY

SWS

Experimental test on swimming pool