Filter Basin Rehabilitation

Maintenance work for sand filter

This rehabilitation work solves problems in filtration facilities and serves as a basic tool for realizing the supply of safe drinking water. The effect is as follows:●Reduction of burden on Environment

No more new filter media and no more industrial waste. It is hard to procure new filter media due to environmental protection in Japan.

●Cost Advantage

Achieve cost reduction to do rehabilitation work rather than media replacement. In case a large amount of filter media is needed, the bigger the purification plant, the higher the cost advantage.●Washing capacity

Propose the best media washing solutions and washing machines for different media conditions. Washed sand medial has similar capacity with Manganese.

Process

Step1. Examination : Examine filter bed and filter media and propose the best rehabilitation work

Step2. Take media out : Following the construction, take filter media out

Step3. Cleaning and Repair : Maintenance work in the filter ( wall, underdrain, surface washing pipes etc. )

Step4. Media washing : Washing and sieving according to the media condition

Step5. Restore media : Install the washed clean media to the filter bed and finally examine it

Take out media from bed

Take out media from bed

Repair underdrain

Wash empty filter basin

Install washed media again

Rehabilitation Work for Media Washing

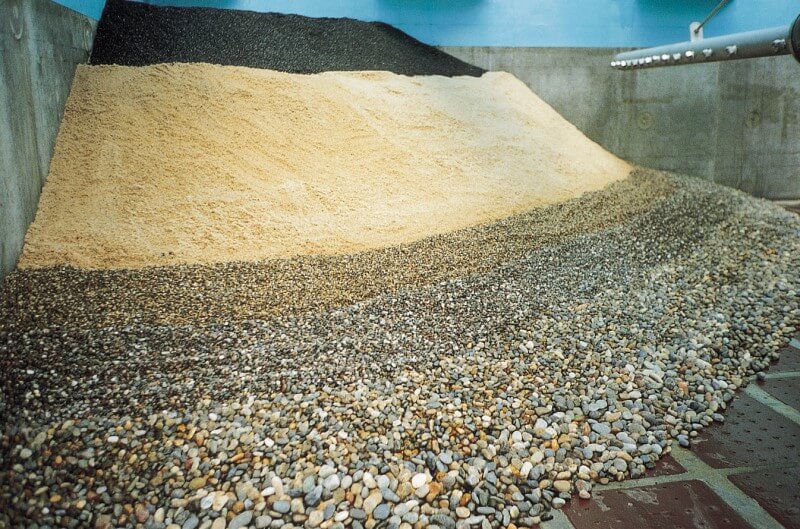

Step1. Washing and Sieving of media : Sieving filter media to separate Anthracite, Filter sand and gravel for each

Step2. Decide washing method : Consider the best washing solution and decide proper system based on the examination result

“SIPHON WASHING System” which can exfoliate attached sludge without particle crushing.

Recycle work : ASAKA Water Purification Plant Tokyo Metropolitan