Hyper Tank

Optimizes water quality using a high flow speed.

The quality of the filter material plays an important role when groundwater is treated to become high quality water for drinking and food manufacture, or in the pre-treatment of ultra-pure water.

As a specialist filter maker, we have an abundance of high quality filter materials and are well versed in groundwater treatment technologies, and have developed a hyper-tank that can even deal with the high treatment volumes associated with high flow speeds.

The combination of optimized filter materials and a high flow speed system results in the highly efficient removal of iron, manganese, and fine particles, etc.

Furthermore, our cooperating partners can assist if it becomes necessary to conduct treatment experiments.

Features

- Advanced water treatment by using optimum combination of filter media

With our full knowledge of the properties of the substances to be removed, such as naturally occurring organic colored water (humic substances), we can suggest an optimum filter media and optimum configuration of filter layers. - Excellent durability achieved by stainless steel tanks

All liquid-contacting parts in Hyper Tank are made of SUS304, exhibiting excellent durability. - High flow rate enabling large-scale treatment

①A high flow rate up to 25m/h enables a large volume of water to be treated in a small tank.

②A high iron concentration exceeding 10mg/L can be treated in a single column.

③The amount of backwash water can be reduced to two-thirds to half of those in conventional systems.

④Space required for installation is smaller compared to conventional systems, so it can be installed in small areas.

Actual Example

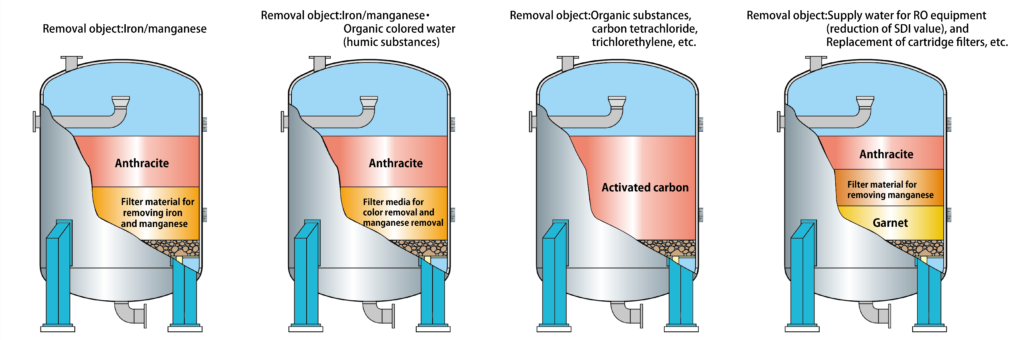

- Removal object: Iron/manganese

| Deferrization process (chlorine oxidation method) | Iron contained in well water mostly exists in the form of ions (colorless). Since iron ions are susceptible to oxidation, they are instantly oxidized by injecting sodium hypochlorite (NaClO, oxidizing agent) and converted into insoluble ferric hydroxide (rust-colored), which is captured and removed by dual filter media for deferrization. |

| Demanganization process (contact oxidation method) | Like iron, manganese contained in well water also exists in the form of ions. Unlike iron, however, manganese is not readily oxidized by sodium hypochlorite alone, so it is instantly oxidized using the catalytic power of high-grade manganese filter media at the surface of the filter media and converted into insoluble manganese dioxide hydrate (black) to be captured and removed. |

- Removal object: Iron/manganese/organic colored water (humic substances)

| Deferrization/demanganization process | Over 90% of well water contains both iron and manganese. Iron is removed via the chlorine oxidation method by injecting sodium hypochlorite, and manganese is removed via the contact oxidation method. Filter media are arranged in dual configuration to remove iron in the upper layer and manganese in the lower. |

| Color (humic substances) removal process | Organic colored water (humic substances) in well water exhibits a pale brown color. Using Color Cutter G (manganese dioxide with beta crystal structure) effective for removing humic substances as a catalyst in the presence of sodium hypochlorite, the color component is oxidized and decomposed to obtain clear and colorless water. |

- Removal object: organic matters/carbon tetrachloride/trichloroethylene/tetrachloroethylene

| Adsorption process Activated carbon | Organic matters (TOC, COD components), trihalomethane precursors and contaminants such as trichloroethylene, tetrachloroethylene, carbon tetrachloride and benzene are adsorbed and removed by high-quality activated carbon. Chlorine remaining after chlorine treatment is also removed. |

- Usage: Feed water for RO system (reduction of SDI value)/alternative to cartridge filters

| Particulate removal process (coagulation filtration method) | Submicron particles of iron, manganese, and clay substances contained in well water are removed by adopting suitable filter media particle size and filter layer configuration with high filtration precision to produce water of high quality. |