SIPHON TANK

Our SIPHON TANK realizes a balance between “considerations for the global environment” and “cost reduction.”

No Required filter media.

Maintenance costs can be dramatically reduced.

Contributes to achievement of zero emissions, solutions to environmental problems, and addressing ISO14000.

The filtration system is used for small water treatment systems or by private companies. The filter media is replaced every six months to five years. These used filter media can be recycled if they are washed and rehabilitated. However, they are usually disposed of as industrial waste due to problems such as space for installing a washing system and costs for washing filter media. Therefore, we developed the “SIPHON TANK,” which is a filtration system that can produce filtered water of stable quality without replacement of filter media. Since filter media are always kept clean, there is no need to dispose of used filter media as industrial waste. It serves as a stepping stone to a solution to environmental problems and toward the achievement of zero emissions as advocated by ISO14000. It is also expected to significantly reduce maintenance costs, including the cost for replacement of filter media and the cost for backwashing.

CHARACTERISTICS

- No Required Replace Filter Media.

The combination of “SIPHON WASHING system” which is kneading washing among filter media particles and backwashing keeps filter media always clean in the tank. Therefore, periodical filter media replacement is not necessary. - Since filter media are always clean, consistent water quality can be achieved.

SIPHON TANK can keep filter media at the same condition as new sand. Therefore, consistent filtration is possible. In addition, SIPHON TANK has a structure that prevents unevenness of supporting gravel. Therefore, the problems due to unevenness including short pass do not occur. The amount of filter media flowing out due to sludge deposit is also reduced and the capacity to capture suspended substances does not deteriorate. - Maintenance cost is dramatically cut.

“Cost for filter media replacement work,” “cost for disposing of used filter media as industrial waste,” and “cost for purchasing new filter media for replacement work” are not necessary. Therefore, maintenance costs can be dramatically reduced. - The amount of backwash water can be significantly reduced.

Since SIPHON TANK exfoliates hard adhering suspended substances by “SIPHON WASHING” and conducts backwashing only for rinsing the suspended substances away, the amount of backwash water volume can be significantly reduced in comparison with the conventional filtration systems. - SIPHON TANK serves as an important stepping stone toward the achievement of Zero Emissions.

Filter media can be used semi-permanently. Therefore, there is no longer a need to dispose of used filter media as industrial waste. SIPHON TANKs are “eco-friendly” filtration systems that significantly contribute to a solution to environmental issues and addressing ISO14000. - Maintenance costs for water quality can be significantly reduced.

Suspended substances never accumulate in filter media. The accumulation of suspended substances due to longtime use and the fixation of filter media to each other due to organic matters, etc. can be prevented. Because water quality is always stable, the costs for water quality analysis or analysis of the status of filter media can be significantly reduced. - Fixation of filter media is prevented.

Since fixation of filter media is prevented, SIPHON TANK can be used not only for water supply but also for sewage/wastewater treatment - SIPHON TANK reduces workload in the following facilities.

Treated water by SIPHON TANK is stabilized so that the burden on the subsequent membrane system can be reduced and extended its life. - Easy Maintenance

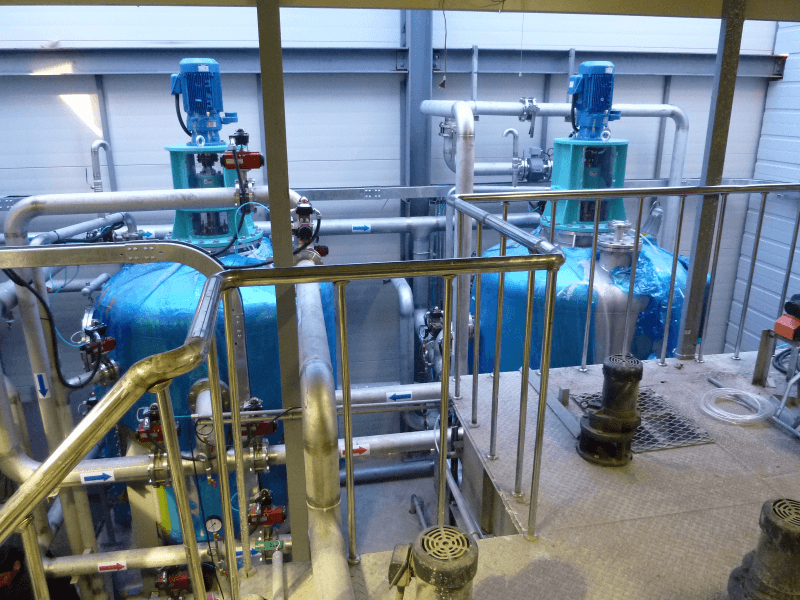

Cartridge-type screws are used for SIPHON TANK. Therefore, the maintenance work is easy. - Stainless SUS304 Tank

For the wetted part, SUS304 is used under the standard specifications. Since Steal Strength (SS) coated with epoxy tar, etc. is used for filtration systems in general, significant cost and time is necessary for curing. However, such mending of coating is not necessary for SIPHON TANK.

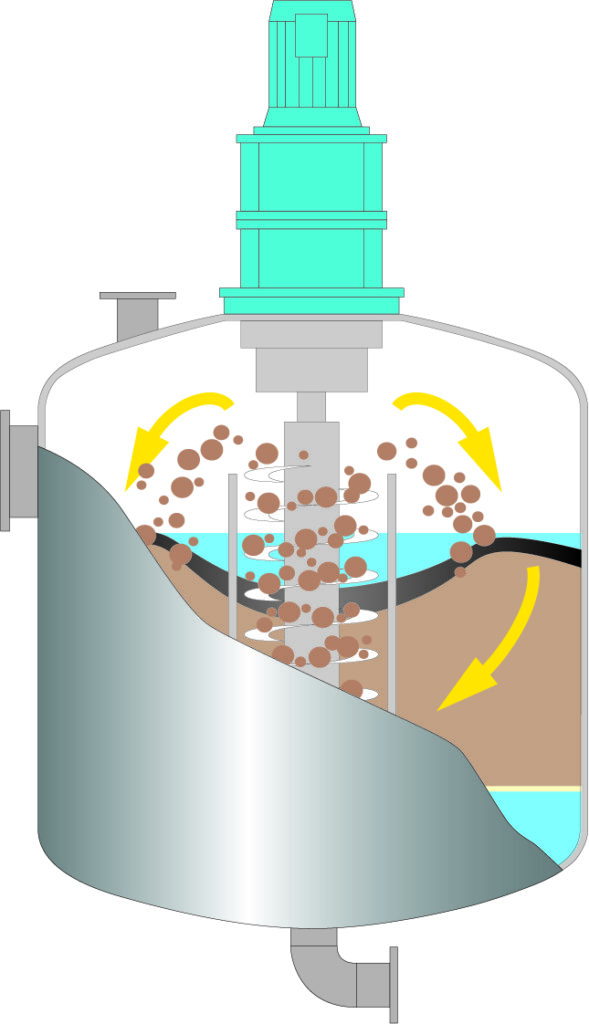

SIPHON WASHING

Since the principle of SIPHON WASHING was introduced to the filtration system and was systematized, filter media is always kept clean. Therefore, filter media replacement work is not necessary. Filter media is washed by SIPHON WASHING, and backwashing is conducted only for rinsing, so maintenance costs, including the cost for backwash water, can be largely reduced.

The unevenness of supporting gravel is prevented by the unevenness prevention plate.

| Principle of SIPHON WASHING | |

|---|---|

|  |

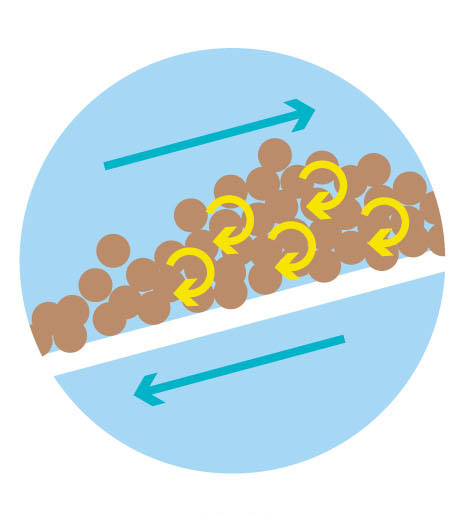

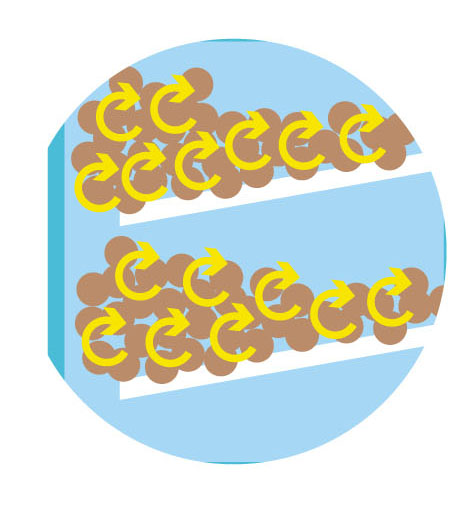

| A vortex flow is generated By the gravity of particles and the lift force created by the screw. | Particles running outward due to the centrifugal force generate a vortex flow. |

The sand washing system creates two kinds of vortex such as vertical and horizontal vortices that cause sand particles to knead each other in a three-dimensional (3D) washing action. The vertical vortex is created in each sand particle by gravity and scooping up force. The horizontal vortex is created in each particle by centrifugal and returning force after hitting the side of inner cylinder. These vortices make sand particles to knead and rub each other in a three-dimensional washing action.

UNIQUE PERFORMANCE

- High cleaning effect

Backwashing and air-washing can only prevent clogging at best. However, by “SIPHON WASHING,” even stubborn sludge can be removed because filter media wash each other with a kneading action. Therefore, filter media can be cleaned up to the degree of turbidity comparable to that of new sand (JWWA A-103). - Filter media is not crushed when washing with the “kneading method”, which has an optimum cleaning effect.

Due to filter media washing each other using a kneading action, filter media will not be crushed while only sludge attached to the surface is removed. Therefore, filter media can be kept in the condition close to that of new filter media. - The outflow of exfoliated sludge can be avoided or significantly reduced

Due to the vigorous cleaning effect, the outflow of exfoliated sludge into filtered water can be avoided or significantly reduced, and a constant and consistent water quality can be achieved. - The outflow of filter media is significantly reduced.

Filter media run off during backwashing has a low specific gravity, and an extremely large amount of sludge and manganese are attached to it. The run off occurs regardless of particle sizes. Siphon Tanks can significantly reduce the outflow of filter media by keeping filter media in the same condition as new filter media.

Process Flow SIPHON TANK

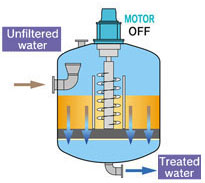

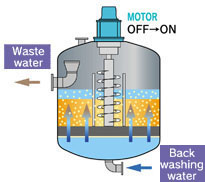

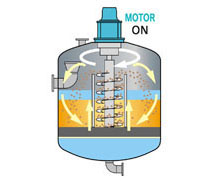

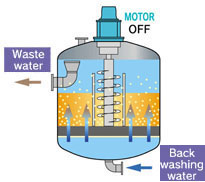

| ①FILTRATION | ②BACKWASHING | ③SIPHON WASHING | ④BACKWASHING |

|---|---|---|---|

|  |  |  |

| As with conventional filtration systems, filtration is conducted by downflow with pressure. Although the inner cylinder and the screw are placed at the center, filter media are also packed into this area. Filtration is thus conducted by the entire filtration system. A Siphon Tank can treat the same amount of water as conventional filtration systems of the same size. | Backwashing is first conducted for a short period of time to fluidize filter media, and then SIPHON WASHING is conducted. | Filter media are washed with each other by a kneading action in a three-dimensional washing action by the rotation of the screw. | After SIPHON WASHING, backwashing is conducted to rinse the sludge away. The sludge is completely exfoliated from filter media by SIPHON WASHING. Therefore, the sludge can be easily removed by rinsing. Note: When backwashing is conducted, the multi-layer of filter media by anthracite is also possible. |

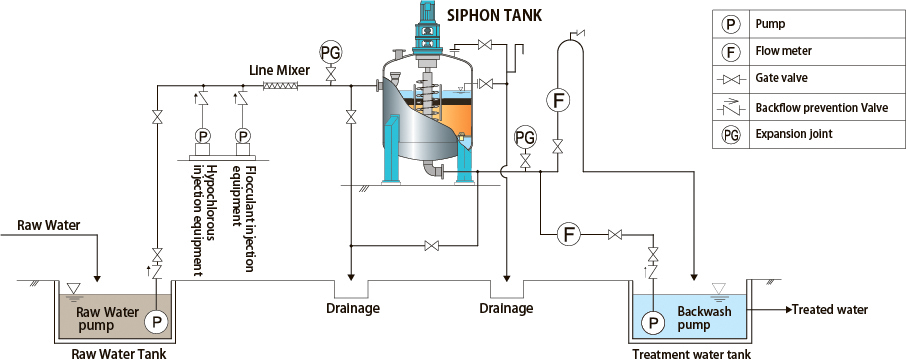

Example Flow Sheet of a SIPHON TANK

Line Up:Standard Specifications of SIPHON TANK

| TYPE | BODY DIAMETER (mm) | CARTRIDGE DIA. (mm) | MOTOR(kW) | Amount of Treated water CBM/Hour CBM/Day | |

|---|---|---|---|---|---|

| ST-700 | φ700 | φ200 | 3.7 | 3.8m³/h | 87.4㎥/d |

| ST-900 | φ900 | 6.3m³/h | 144.9㎥/d | ||

| ST-1000 | φ1000 | φ250 | 5.5 | 7.8m³/h | 179.4㎥/d |

| ST-1200 | φ1200 | 11.3m³/h | 259.9㎥/d | ||

| ST-1500 | φ1500 | φ400 | 7.5 | 17.6m³/h | 404.8㎥/d |

| ST-1600 | φ1600 | 20.0m³/h | 460.0㎥/d | ||

| ST-1800 | φ1800 | 25.4m³/h | 584.2㎥/d | ||

| ST-2000 | φ2000 | φ500 | 11.0 | 31.4m³/h | 722.2㎥/d |

| ST-2200 | φ2200 | 37.9m³/h | 871.7㎥/d | ||

| ST-2500 | φ2500 | φ700 | 18.5 | 49.0m³/h | 1127.0㎥/d |

| ST-2800 | φ2800 | 61.5m³/h | 1414.5㎥/d | ||

| ST-3000 | φ3000 | 70.6m³/h | 1623.8㎥/d | ||

Reference

Public sector (Municipality)

Water Purification Plant in HITACHI City

ST-1500

Drinking Water supply

17.6CBM/hr (410CBM/day)

Water Purification Plant in AOMORI City

ST-1000

Drinking Water supply

4.3CBM/hr (100CBM/day)

Water Purification Plant in GERO City

ST-900

6.3CBM/hr (150CBM/day)

Private sector

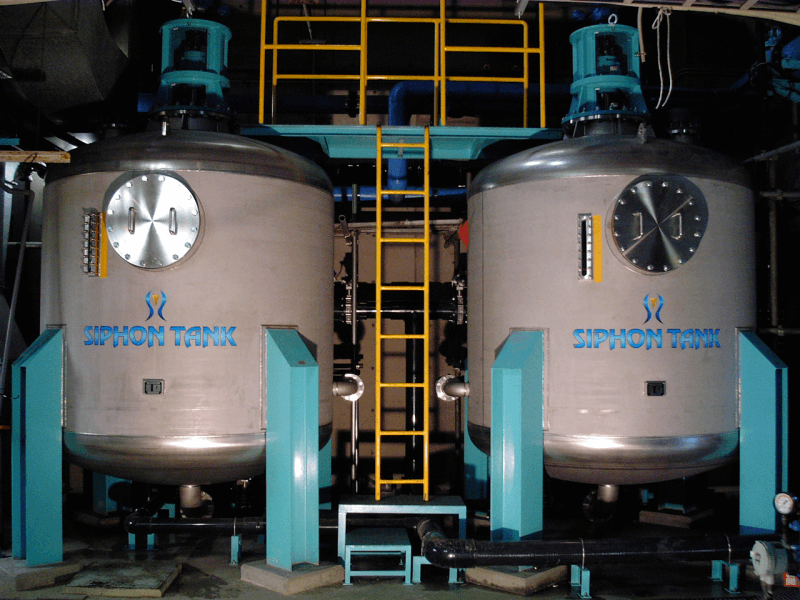

SONY Corporation

ST-2200 x 2units

Industrial process water treatment

40CBM/hr/each

Chemical Company

ST-1200

Industrial process water treatment

15CBM/hr

YAZAKI Corporation

ST-1500

Plating wastewater

20CBM/hr

YAZAKI Corporation

ST-900

Plating wastewater

4CBM/hr

Automotive Component Company

ST-1600

ACST-1800

Dissolved-air flotation treated wastewater

20CBM/hr

PET REFINE TECHNOLOGY Company

ST-2200

Pretreatment for pure water

40CBM/hr

Overseas

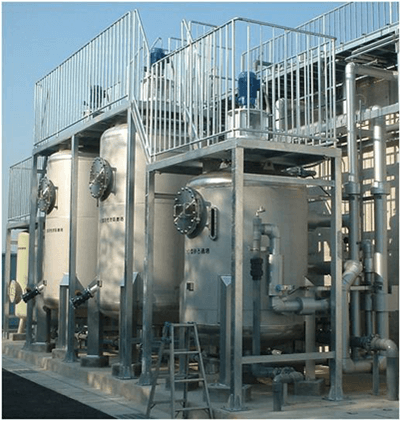

KOREAN Company

ST-1600x 2units

Industrial wastewater

Japanese Copper Factory in Thailand

ST-900

Industrial wastewater

4.5CBM/hr